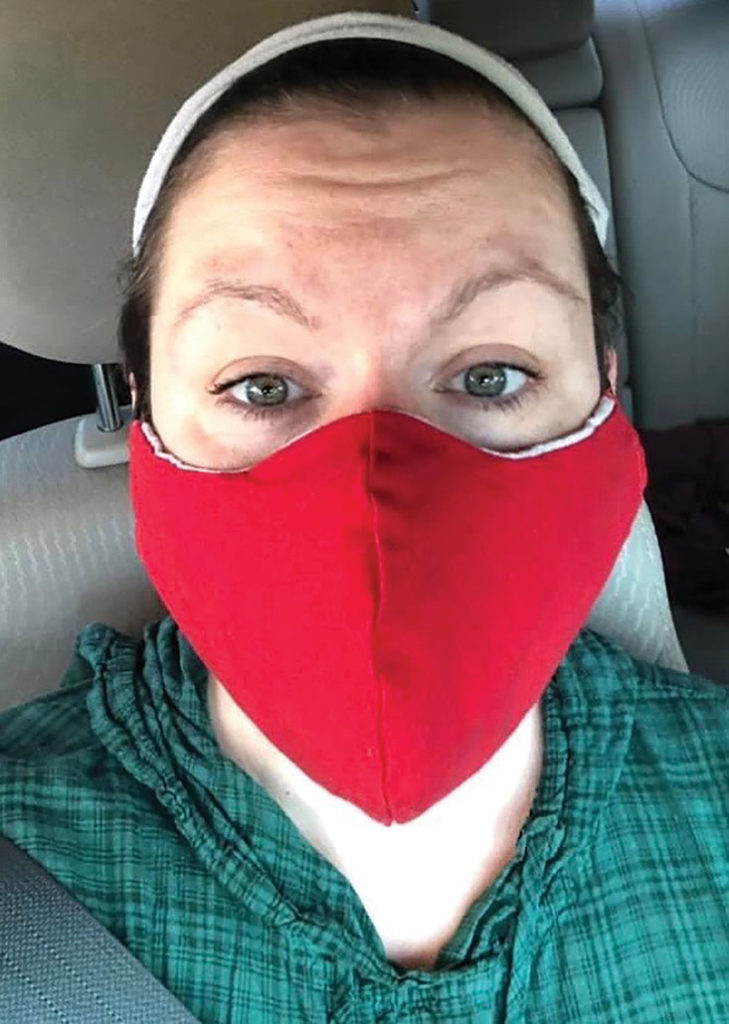

(Photo by John C. Cotey)

FOR three months, Cory Revoldt’s Christmas present sat unopened. Her plans to unleash her crafty side in 2020 had been sidelined by a busy work schedule and having three kids transition to online learning at home. “One day,” she kept saying to herself.

A day in late March, when she had a conversation with her brother, Jacob Hennings, turned out to be that day.

Jacob, a doctor in Chattanooga, TN, working on the frontlines in the battle against Covid-19, told Cory not to let her family out of the house without wearing masks.

It wasn’t just because he told Cory that she needed to take the novel coronavirus seriously, but also because two of her three daughters and her husband, Chris, also suffer from asthma.

Chris also continued to work outside of their house.

Because there was a shortage in Florida, and because the U.S. Centers for Disease Control (CDC) & Prevention began recommending that everyone should wear cloth face coverings in public to help prevent the spread of Covid-19, Cory figured it was finally about time to open that Christmas present — a Singer Heavy Duty 4423 sewing machine.

Cory began by making masks for her family, which lives in Easton Park off Morris Bridge Rd., and hasn’t stopped since. Seeing that there was a shortage at local hospitals, Cory and her daughters — Teagan, 12, Kylie, 15 and Avery, 16 — have been making masks every night. They made their first donation to Gentle Hands OB/GYN, then handed out a handful of masks to the workers at The UPS Store, and recently passed the 100-mask mark with their donations to the Moffitt Cancer Center.

All of her masks, like most of those made from fabric, are washable and reusable.

Remarkably, Cory didn’t know how to sew when the project started. She got the machine for Christmas to learn. She essentially took a 48-hour online crash course via Facebook, YouTube and Joann.com.

“Once we knew there was a need, I was like, okay, let me figure out this sewing machine,” Cory says. “It was frustrating at first. But now, it’s become a labor of love.”

—–

The Revoldts are members of a large nationwide army that has swept into action as hospitals everywhere have been fretting over a shortage of protective equipment when it comes to fighting the coronavirus.

It may not be Rosie the Riveter sweating it out in a World War II shipyard, but living rooms and dens all across the country have been converted to mini mask-making factories.

While homemade masks aren’t a substitute for the high-grade N-95 masks or even regular surgical masks when it comes to filtering out the coronavirus, they do offer some protection and, according to the CDC, can help prevent the spread of the virus.

Most of these modern day riveters are experienced seamstresses eager to jump into the fray.

(Photo courtesy of Katie Johns)

Heritage Isles resident Katie Johns, who owns a sewing business that makes children’s clothing, said she was inspired to begin making masks when she learned of the local shortages. She also enlisted the help of her 5-, 7- and 9-year-old daughters, and to date, has made more than 200 masks and donated them to individual nurses at Moffitt and the James A. Haley Veteran’s Hospital.

It began with a simple comment on Facebook by Katie and, almost immediately, she was flooded with requests from medical professionals and friends.

“One of my neighbors is a doctor, and he was so grateful just to have a mask,” she says. “There is definitely a need for them, and it’s nice to help.”

Katie says there are a lot of considerations to take into account when making masks. She says they need to be breathable yet safe, comfortable for doctors and nurses who wear them for entire shifts at a time, and they have to mold to the bridge of the nose so goggles and glasses don’t fog up.

She says a massive underground sewing community is fine-tuning the process every day. For example, The Mask Project of Tampa Bay, a group on Facebook, has more than 4,500 members and has raised more than $7,600 to purchase materials to make more masks.

Thankfully, says AdventHealth Connerton (AHC) nurse Amy Zweil, there is an abundance of Corys and Katies in the New Tampa and Wesley Chapel area.

When Amy, a Live Oak resident, posted online that many of the nurses at her hospital were looking for cloth masks to wear over their hospital-issued masks to help preserve them, her post received more than 100 comments from people volunteering to make and drop off masks.

Within an hour of the post, one of her neighbors dropped off a mask in Amy’s mailbox. Another dropped off some masks, as well as hand sanitizer and gloves.

“I was surprised at the response,” Amy says. “It was overwhelming.”

Amy received a variety of masks, some with elastic that hooked around the ears and others that tied in the back, which can be less painful after hours of use.

She also was offered N-95 masks but AHC is a long-term acute care hospital and not taking Covid-19 patients. She suggested donating the masks to someone who needs them.

She received such an outpouring of generosity that she began directing people to others who needed masks.

Irma Gill of Hunter’s Green was one of those who made masks for Amy, as well as for many other people.

A tutu designer for professional ballerinas, Irma was part of a large Facebook group of designers from all over the world. Back in March, during one chat, one of the designers in Italy told the group she was switching to making masks instead of designer clothes because the coronavirus was ravaging her country.

Irma wondered if, eventually, that would be her calling as well.

When Amy posted about her need for masks, Irma started sewing. She made 40 masks, all with three layers of cotton that were big enough to fit snugly over the large N-95 masks. By her fourth week of sewing masks, she had made more than 200.

Irma grew up sewing men’s shirts in a factory in Mexico until she came to the United States at the age of 17, so producing en masse was nothing new to her.

She graduated from San Diego State University with a degree in health education, which came in handy when she began designing masks for medical workers.

She is currently making masks for nurses working in prenatal care at St. Joseph Hospital, as well as for some other nurses, although she says it is getting harder and harder to find the right material.

But, Irma says she has no plans to slow down.

“I will find something,” she says, “even if I have to take my curtains down and use those.”

Finding the right material requires patience, says Cory. Fabric and elastic can be hard to come by.

Before masks became a big thing, she said the first time getting fabric was easy.

The second time, she says she stood in line for two hours — six feet apart, of course — at Joann Fabrics, which was only allowing 10 people in the store at a time.

Now, she uses curbside pickup, although she says it’s harder to use coupons than it would be to bring them inside the store. Proudly, she says she still managed to reduce her last purchase from $186 to $111.

Avery, a junior at Wharton, recently got her driver’s license and made the last pick up while her mother and sisters cut and sewed the remaining fabric at home.

It’s a team effort at the Revoldts. They work together measuring and cutting the fabric. Kylie will cut and pin the three 3″x 6″ layers — two regular cotton layers and one muslin cotton, a lighter and looser weave — which Cory will sew before adding shirt ties. Even husband Chris has made sacrifices, surrendering many of his tee shirts, which are being cut into strips and made into more comfortable ties.

Cory still has the first mask she ever made. The stitching takes a few detours across the white and pink- flowered pattern, and the pleats aren’t perfect like her on latest masks.

“The pleats are still the hardest part,” Cory says, laughing.

Her masks now are a dramatic improvement over that first effort. Cory and her daughters have just about mastered the art.

“I’m very proud of my girls, I’m not going to lie,” Cory says. “I’d like to think this has brought out the best on all of us.”

The Revoldts wash, sanitize and press their masks before placing them in labeled Ziploc bags. They are placed outside where two friends who also live in Easton Park and work at Moffitt will swing by and pick them up on their way into work.

As wearing masks becomes more and more common — an attempt to make them mandatory in Hillsborough County was defeated, but wearing them is still recommended by everyone from the CDC to members of President Trump’s own Coronavirus Task Force that they be worn by everyone who goes out in public — Cory is getting more and more requests from friends.

Her first masks were made with fabric depicting things like sea turtles, bees and lady bugs. She added more masculine patterns like sharks and bi-planes for the male doctors. As she makes more masks for friends, she is stocking up on Avengers prints, Mickey Mouse and Trolls.

“Now that this is becoming the new socially acceptable look, people will want something with some personality,” Cory says.

One of her side projects is making masks for everyone on Teagan’s club soccer team. One of the other mothers mentioned that she had tried, but grew frustrated.

A day later, that same mom dropped her Singer 132 featherweight sewing machine off at the Revoldts home. Now, Teagan and Cory can both sew at the same time.

“It’s starting to look like a sweatshop in here,” Cory joked.

Last week, with two Singer machines humming along in stereo — chuka chuka chuka — the Revoldts’ pile of what will be 100 masks to donate to Tampa General Hospital began growing higher.

The post A Call To Action appeared first on Neighborhood News.

Customer Reviews

Thanks for submitting your comment!